Their fundamental properties include minimal ON resistance, high temperature, high frequency, and high voltage performance which makes them superior compared to silicon.

Which segment accounted for your largest silicon carbide semiconductor devices market share? b. Asia Pacific dominated the silicon carbide semiconductor devices market with a share of thirty.

When its grains are bonded together within an electric arc furnace, the ensuing product is an extremely hard material with excellent thermal conductivity, thermal shock resistance, and chemically inert abrasion resistance.

All my friends will be so jealous when they see The gorgeous jewelry I’m capable of make with my newly polished rocks.

Use a respirator with type P100 (United states) or P3 (EN 143) cartridges to be a backup to engineering controls. Possibility assessment should be performed to determine if air purifying respirators are acceptable. Only use equipment tested and authorized under acceptable government standards.

About the same time Acheson made his discovery, Henri Moissan in France produced a similar compound from a combination of quartz and carbon; but in a very publication of 1903, Moissan ascribed the original discovery to Acheson.

Sooner or later, on the other hand, the change to 200-mm wafers may very well be a tailwind. The manufacturers that achieve mastering the 200-mm evolution will recognize a much lower cost per square mm for wafers produced, and theoretically better yields inside the long run.

The only real certainty is that the number of automotive-grade MOSFET wafers will be significantly lower than the introduced manufacturer nameplate capacity.

Of course the first thing you’ll need is often a rock tumbler. Rotary tumblers are classified as the most common for beginners and will polish small to medium sized rocks.

S. and European vehicles �?i.e. lasting the lifetime with the car or truck without leaking. These components are manufactured by regular high volume pressing and injection moulding methods to fulfill the economic constraints on the application.

Due to its wide range of applications in power electronics, using SiC is anticipated to boost significantly. The growing finish-uses of silicon carbide semiconductor devices in emerging industries, such as the electric auto and power electronics industries are anticipated to drive the market growth during the forecast period.

More recently, it has found application in refractory linings and heating elements for industrial furnaces, in wear-resistant parts for pumps silicon carbide solar cell and rocket engines, and in semiconducting substrates for light-emitting diodes.

As an example, electric car or truck manufacturers are incorporating silicon carbide components to realize cost and energy efficiency in inverters, chargers, and auxiliary loads along with decreasing the battery size, bringing about new product launches with the companies.

have one pound of coarse, medium and fine grit plus eight ounces of TXP polish. This is sufficient supplies to tumble around four three-pound barrels of rocks.

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Yasmine Bleeth Then & Now!

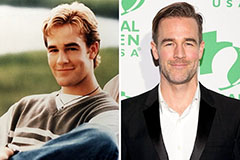

Yasmine Bleeth Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Shannon Elizabeth Then & Now!

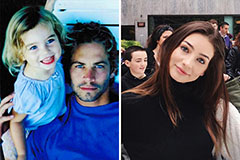

Shannon Elizabeth Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!